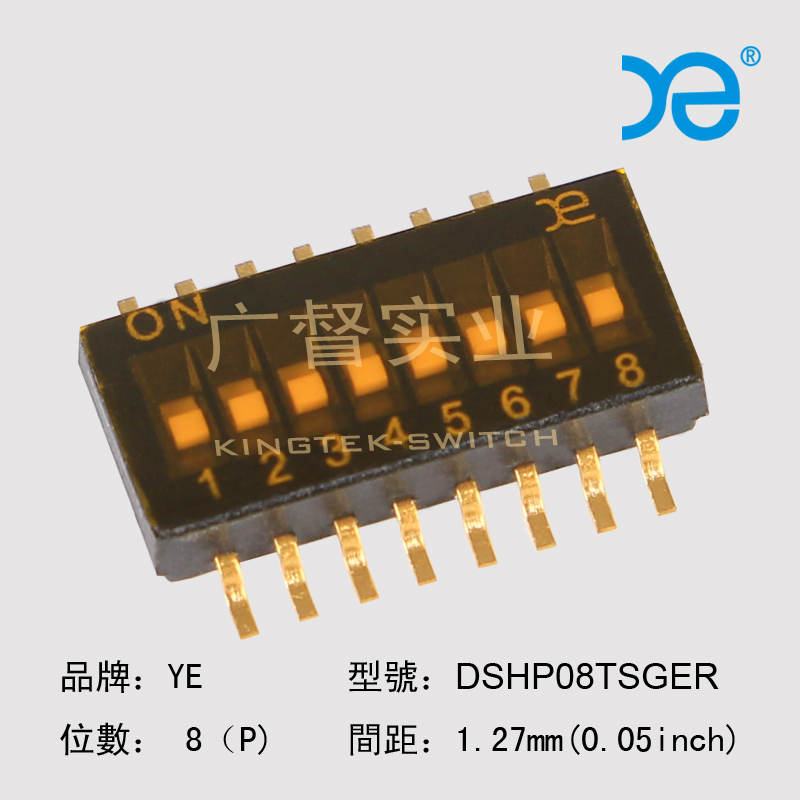

Please note the following when using the ye series DIP switch, if you need to change the value setting.Do not use the oil or wet hands to operate the button.If you want to clean the molding resin shell and other surface dirt, it is recommended to use alcohol to clean up.When cleaning, please avoid alcohol infiltration inside the DIP switch.In particular, do not touch the charging area in the energized state.To prevent short circuit, be careful not to connect multiple power supplies to a single switch.

How does ye welding the DIP switch:

1. Hand welding: no more than 350 degrees Celsius no more than three seconds or 270 degrees Celsius within 5 seconds. The following are the same as the "

2.Reflow soldering: 260 degrees ± 5 degrees within 10 seconds, please put the push button in the "OFF" position during welding and cleaning.

In addition, when removing the connection, use a screwdriver to remove the upper and lower jaws.Do not press the push button while operating. Because it may make it fall.Dropping may cause problems such as denier of the terminals, breakage of the printed circuit board, and breakage of the resin claws on the connection side of the switch, so be careful not to drop it.

Prev:KINGTEK switch has been used DIP mode

Next:How to choose a high quality DIP switch?